Product Description

Roach 196G Galvanized Gravity Roller Conveyor – 1.9" Diameter, 16-Gauge Steel

The Roach 196G Gravity Conveyor Bed is a heavy-duty, non-powered conveyor system engineered to transport cartons, boxes, bins, and other flat-bottom items with ease. Ideal for warehouses, distribution centers, and manufacturing environments, this galvanized steel conveyor delivers strength, durability, and efficiency—without relying on electricity.

Built to Last

Manufactured with 1.9" diameter, 16-gauge galvanized steel rollers and a rugged steel frame, the Roach 196G is designed for high-performance, low-maintenance operation. Its smooth-rolling surface ensures consistent product flow, making it a cost-effective choice for improving throughput and reducing manual labor.

Common Applications:

- Shipping & receiving stations

- Packaging and assembly lines

- Warehouse storage & order fulfillment

- Workstations in industrial facilities

Key Components of the Roach 196G Gravity Conveyor Bed:

- Rollers: 1.9" diameter x 16-gauge galvanized steel rollers with smooth swaged ends.

- Frame:

- Set high: 3-1/2" x 1-1/2" x 10-gauge painted steel channel

- Set low: 4-1/2" x 1-1/2" x 10-gauge painted steel channel

- Frame Capacity:

- 250 lbs. per roller

- Up to 1,300 lbs. live load per 10' section (10' support spacing)

- Up to 3,200 lbs. live load per 10' section (5' support spacing)

- Bearings: Integral plain ball bearings, zinc plated, grease packed.

- Couplings: Butt type.

- Axles: 7/16" hex shaft, spring loaded.

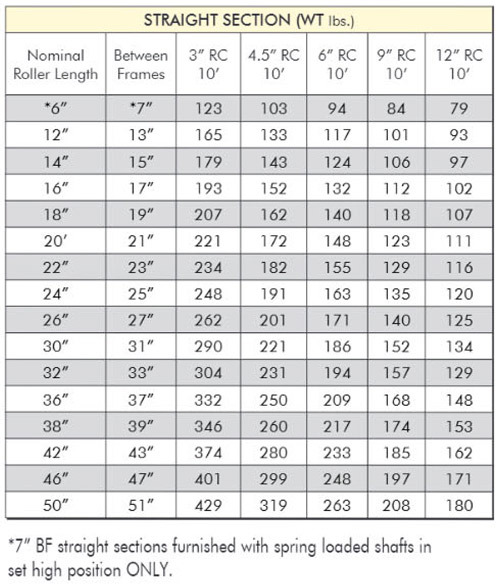

Available in various lengths, widths, and roller configurations, the Roach 196G gravity conveyor can be tailored to meet your facility’s specific layout and load requirements.

Optional Equipment:

- Support Stands - Sold Separately : Roach SM series medium duty

- Knee Braces

- Guard Rail

Additional safety information:

To prevent pinch points that exist when gravity conveyors are permanently attached to power conveyors, use connector brackets with safety pop out rollers. Call us for more information at (320) 485-4974.