Product Description

MHS Curve Center Support

MHS Curve Center Conveyor Supports

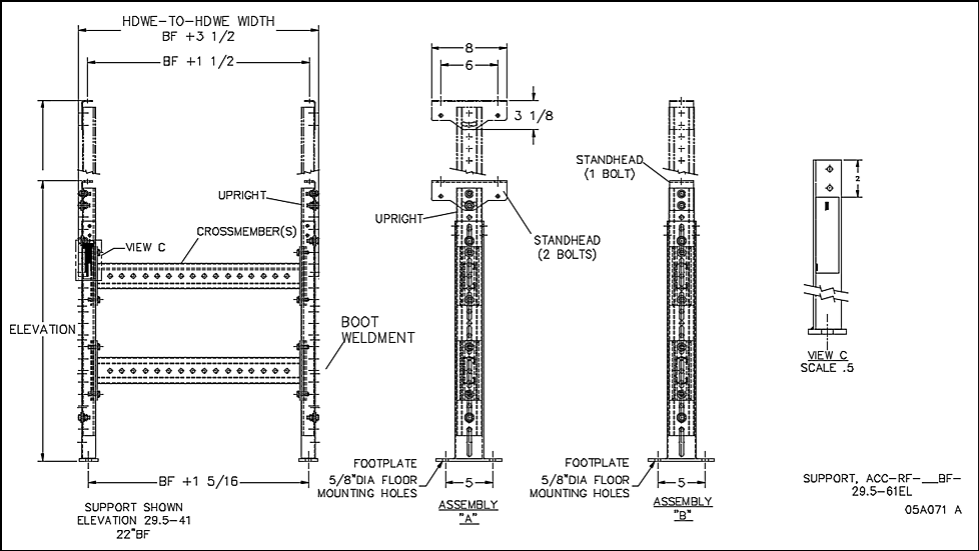

Roll formed curve center supports feature a modular bolt together design which allows for ease of adjustability. The roll formed shape also has a pattern of holes that give flexibility for knee bracing, sway bracing, running safety cables, and hanging of conduit.

Key Features:

- Standhead: Formed steel angle. Two slots in top flange are for bolting to bottom flange of bed sections. Curved slot in side permits pivot adjustment up to 30 degrees in either direction.

- Leg upright: Steel channel, 7/16” diameter holes for bolting to vertical slots in boot and standhead.

- Boot: Steel channel boot upright welded to footplate. Two 5/8” diameter holes in footplates for permanent floor mounting. Vertical slots for bolting to leg uprights.

- Capacity: 1500 lbs., typical, per standard Roll Formed floor support

- 1.5" Center to Center: Designed with precise spacing for optimal functionality.

Features Benefits:

- Bolt-together construction: Can remove & re-install upright or cross-member to fit around existing equipment.

- Allows installation flexibility: Adjust cross-member heights to simplify mounting of cable trays, conduit, piping, etc.

- Mount to options: Roll formed hole patterns on uprights and cross-members provide easy mounting for MHS supplied parts such as knee braces and sway bracing

Product Videos

Specifications

Standard Equipment RF CCS Support Consists of:

(1) Standhead,(1) Boot weldment with footplate, (1) Leg upright (less crossmembers) to support outside channel of curves

Single Leg Supports:

Use single leg supports on 90° and 60° curves

Curves Over 34BF:

Install a standard floor support with crossmember located in the center location of the curve

Hardware Retightening:

All hardware loosened during installation must be retightened to 55 ft. lbs, Failure to retighten may cause structural failure

Safety Precautions:

Block or support the bed while adjusting heights

Load Specifications:

Total load on supports includes MHS conveyor and system live load only, Added equipment weights must be considered by the System Integrator and approved by MHS Conveyor

Capacity Considerations:

Capacities are based on both the weight of the conveyor and the product load, Weights that are not centered will reduce the capacities